- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-02-18 Origin: Site

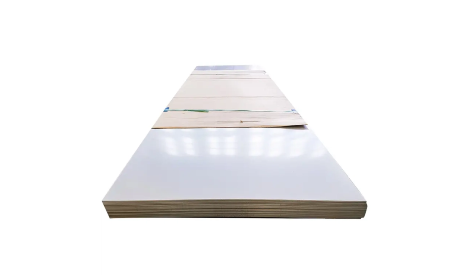

The food and beverage industry is one of the most demanding sectors in terms of materials and equipment. Maintaining high standards of hygiene and durability is essential for ensuring the safety of the products and the efficiency of the processes involved. One material that plays a crucial role in meeting these demands is stainless steel, particularly stainless steel sheets. These versatile, strong, and hygienic materials are widely used in various applications within the food and beverage industry, from processing equipment to kitchen surfaces and packaging solutions.

Stainless steel is a preferred choice in the food and beverage industry due to its unique combination of properties that make it ideal for environments where hygiene and durability are of paramount importance. Here are some reasons why stainless steel sheets are so widely used in this industry:

Corrosion Resistance

Stainless steel's most significant advantage is its exceptional resistance to corrosion. In the food and beverage industry, the constant exposure to moisture, acids, and salts can quickly cause other materials to degrade. Stainless steel, however, forms a protective layer of chromium oxide on its surface that prevents rust and corrosion from penetrating the material. This corrosion resistance is particularly important for food processing equipment, which comes into contact with a variety of liquids, chemicals, and foodstuffs that can cause deterioration in other materials.

Hygiene and Cleanliness

Stainless steel is non-porous, meaning that it does not allow bacteria and other microorganisms to penetrate its surface. This makes it an ideal material for food preparation and storage, where cleanliness is crucial to avoid contamination. Stainless steel is easy to clean and sanitize, meeting the stringent hygiene standards required in the food and beverage industry. Regular cleaning of stainless steel surfaces is efficient and effective, helping to maintain a sterile environment in kitchens, processing plants, and packaging areas.

Durability and Strength

Stainless steel is known for its exceptional strength and longevity. Food and beverage processing equipment, as well as kitchen surfaces, are subjected to constant use and wear. Stainless steel can withstand heavy-duty usage, extreme temperatures, and mechanical stress without losing its integrity. This makes stainless steel an ideal material for everything from industrial food processing machines to countertops and storage units in commercial kitchens. Stainless steel sheets offer both longevity and resilience, reducing the need for frequent replacements or repairs.

Temperature Resistance

Stainless steel's ability to resist extreme temperatures is another reason it is so widely used in the food and beverage industry. Whether in high-heat cooking processes or freezing environments, stainless steel can maintain its strength and shape. This temperature resistance is critical in food production processes such as pasteurization, sterilization, and refrigeration, where materials must endure high or low temperatures without warping, cracking, or losing their performance.

Aesthetic Appeal

Apart from its functional benefits, stainless steel is also aesthetically pleasing. Its sleek, shiny surface adds a modern, clean look to kitchen equipment, countertops, and food storage units. This visual appeal is an important factor in the food and beverage industry, especially in establishments where the presentation of food and the cleanliness of the environment are key aspects of the overall customer experience. The polished finish of stainless steel enhances the appeal of both the products and the space, contributing to a professional and high-quality image for the business.

Stainless steel sheets are used in a wide range of applications within the food and beverage industry. Some of the most common uses include:

Food Processing Equipment

Stainless steel is used extensively in the construction of food processing machinery. From mixers and grinders to conveyor belts and food packaging machines, stainless steel sheets are the material of choice for their strength, resistance to corrosion, and ease of cleaning. In food processing plants, hygiene is critical, and stainless steel ensures that surfaces can be thoroughly sanitized, reducing the risk of contamination. Furthermore, the durability of stainless steel helps to prolong the life of food processing equipment, providing long-term reliability.

Commercial Kitchen Surfaces

Stainless steel is the go-to material for countertops, tables, sinks, and shelving in commercial kitchens. Its resistance to heat, stains, and corrosion makes it the ideal choice for kitchen surfaces that come into constant contact with hot pans, acidic ingredients, and cleaning chemicals. Stainless steel is also highly durable, allowing it to withstand the demands of high-traffic commercial kitchens. Additionally, its smooth surface allows for easy cleaning and maintenance, helping kitchen staff adhere to food safety protocols.

Food Storage and Transportation

Stainless steel is often used in the storage and transportation of food products. Stainless steel containers, tanks, and silos are used to store ingredients, chemicals, and finished food products. These containers ensure that food items are stored in a safe, hygienic environment, protecting them from contamination, moisture, and pests. Stainless steel's non-reactive nature also ensures that it will not alter the taste or quality of the food it holds.

Food Packaging

Stainless steel is also used in the production of packaging materials for food products. While not as common as plastic or glass, stainless steel is sometimes used for packaging beverages, dairy products, and canned foods. Stainless steel cans and bottles offer excellent protection against light, oxygen, and moisture, all of which can compromise the quality of the food inside. Stainless steel's durability ensures that packaged foods are securely protected during transportation and storage, helping to preserve their shelf life.

Brewery Equipment

The brewing industry relies heavily on stainless steel for tanks, fermenters, kettles, and pipelines. Stainless steel is used because it is non-reactive, corrosion-resistant, and easy to clean, all of which are essential in beer and wine production. The material ensures that the quality and flavor of the beverage are not compromised by any reactions between the metal and the ingredients.

Stainless steel sheets provide a number of advantages in the food and beverage industry, making them an essential material in various applications:

Long-Lasting Performance: Stainless steel’s strength and resistance to corrosion mean that it can withstand long-term exposure to harsh conditions, maintaining its performance over time.

Low Maintenance: Stainless steel is easy to maintain, requiring only regular cleaning to keep surfaces sanitary and looking their best.

Eco-Friendly: Stainless steel is 100% recyclable, making it an environmentally friendly material choice for the food and beverage industry. Using stainless steel reduces waste and supports sustainability efforts.

Compliance with Health Regulations: Stainless steel meets all hygiene and safety standards set by health authorities, ensuring that food and beverage manufacturers comply with industry regulations.

In the food and beverage industry, maintaining hygiene, durability, and strength in materials is crucial for business success. Stainless steel sheets provide a perfect blend of corrosion resistance, hygiene, and durability, making them ideal for food processing, commercial kitchens, and packaging. Jiangsu Xinrunhan Steel Co., Ltd. plays a significant role in supplying high-quality stainless steel that meets the strict standards of the food industry. As the sector focuses on safety and sustainability, stainless steel remains essential for ensuring products are safe and long-lasting.

Whether in food processing, restaurants, or packaging, stainless steel sheets fulfill both functional and aesthetic needs. Their versatility, ease of maintenance, and environmental benefits ensure that stainless steel continues to shape the future of the food and beverage industry. With companies like Jiangsu Xinrunhan Steel Co., Ltd. providing top-quality products, businesses can maintain high standards in food safety and operational efficiency.

The Benefits of Using Stainless Steel Sheets in Architecture And Construction

Exploring The Different Grades of Stainless Steel Sheets: Which One Is Right for Your Project?

Stainless Steel Sheets Vs. Aluminum Sheets: Which Is Better for Your Industry?

Stainless Steel Sheets in The Food And Beverage Industry: Hygiene And Durability

Innovative Uses of Stainless Steel Sheets in Modern Industrial Design

Prospects and Development Trends of Cold-Rolled Stainless Steel Coils

What is the Difference Between Stainless Steel and Galvanized Pipe?